Sugar production

Sugar production

Foaming issues during sugar production

During the sugar production process, impurities coming from the soil and the beet can contribute to increased foaming. The foaming causes undesired bottlenecks in production as:

- higher energy costs

- decreased tank capacity

- material loss

- inefficient settling

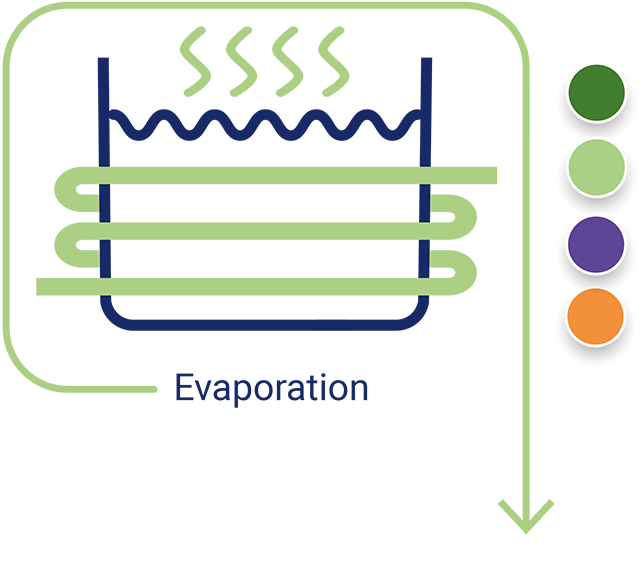

- slower evaporation and crystallization process resulting in higher energy consumption

- extra downtime due to cleaning of equipment

Scaling during sugar production

Scaling occurs during sugar production due to the precipitation of calcium salts or silicates, especially during evaporation. The formation of deposits has the following drawbacks:

- higher energy costs

- higher colors due to longer retention times in the evaporation process

- additional downtime due to cleaning of the equipment

Defoamer, antiscalants and other processing aids

To prevent the negative effects of foaming and scaling, LEVACO developed the following antifoaming agents and processing aids for the food industry:

The demand for organic products is increasing. The sugar factories are trying to keep up with the demand by increasing organic sugar production. To support them, LEVACO developed antifoaming agents that meet the strict requirements of the EU Organic Regulation.

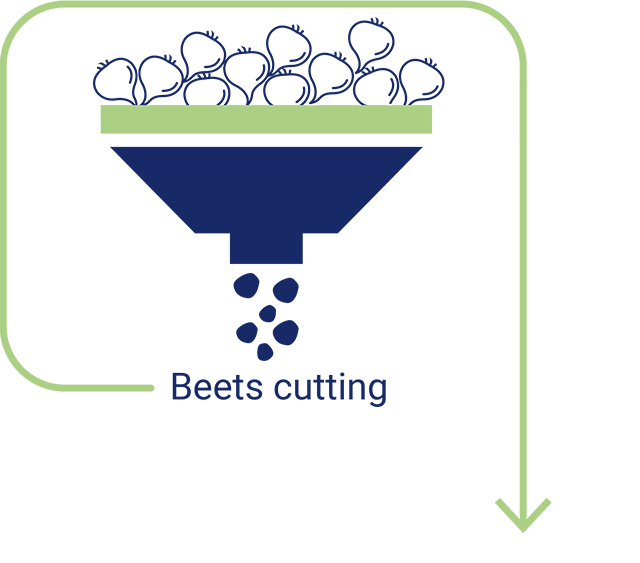

At the beet washing, surface-active substances like saponins are dissolved in the transport water, generating undesired foam. A so-called outside antifoaming agent is used to handle foaming in this cold process.

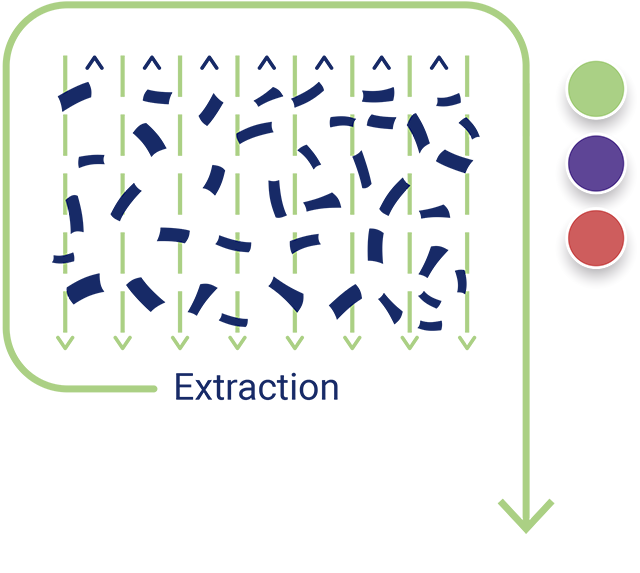

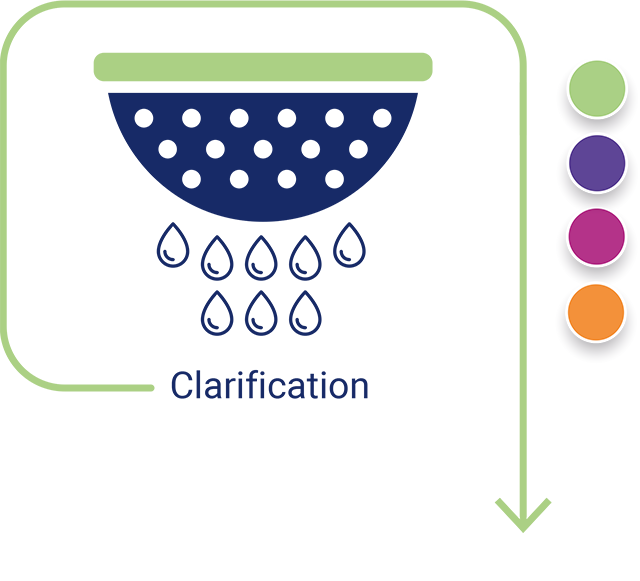

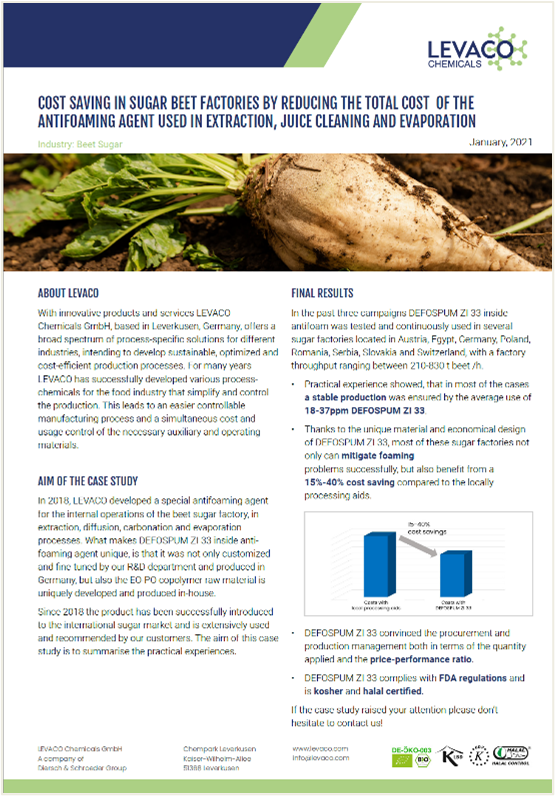

At the diffusion, extraction, carbonation and evaporation processes the process temperatures are much higher than during the beet washing process. Therefore, these processes require a defoamer that performs optimally at these temperatures.

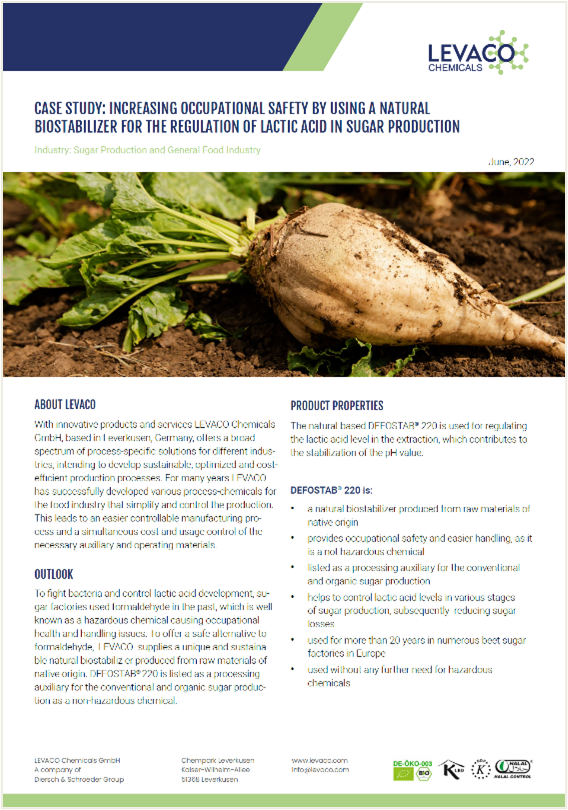

To fight bacteria and control lactic acid development, sugar factories used formaldehyde in the past, which is a hazardous chemical causing occupational health and handling issues. To offer a safe alternative to formaldehyde, LEVACO supplies a unique and sustainable natural biostabilizer produced from raw materials of native origin, listed as a processing auxiliary for conventional and organic sugar production. The DEFOSTAB® biostabilizer can aid or replace formaldehyde to control lactic acid levels in various stages of sugar production, subsequently reducing sugar losses, enhancing occupational safety and easier handling, not being a hazardous chemical.

To enhance the performance of settling tanks in carbonation, water treatment and other processes, flocculating agents are used. We offer a wide range of anionic and cationic flocculants of different molecular weights.

Scale prevents an effective heat transfer in the evaporator stages, leading to increased energy costs and product losses. DEFOSCALE® scaling inhibitor prevents the scale formation in evaporators and heat exchangers. This reduces energy consumption and saves CO2 and costs.

At the pans, a special antifoaming agent called pan aid is used to reduce the viscosity of the syrup, improving the rate of crystallization, thus decreasing energy consumption and increasing productivity.

Chemical cleaning methods are used to remove organic and inorganic deposits such as lime scale, silicates and sugar carbon. DEFOCLEAN® optimizes these processes and makes them more effective and cost-efficient.

Click here for brochures and case studies

To learn more about practical experiences with our processing aids please check our case studies:

Case Study

“Natural biostabilizer in sugar production”

Increasing occupational safety by using a natural biostabilizer for the regulation of lactic acid in sugar production

Case Study

“Cost saving in sugar production”

Cost saving in sugar beet factories by reducing the total cost of the antifoaming agent used in extraction, juice cleaning and evaporation

Case Study

“Efficient antiscaling treatment means energy and maintenance cost savings”

DEFOSCALE® OK: Advanced antiscaling solution for longer, efficient beet sugar campaigns

Case Study

“Biobased Antifoaming Agent for beet sugar production”

Biobased antifoaming agents increase occupational safe and enhance sustainability